| Invention | Year | Inventor/Creator |

| Graham-Desaguliers Dynamometer | 1719 | George Graham and John Desagulier |

| Regnier Dynamometer | 1798 | Edmé Régnier |

| Vehicle Weight Category | Force Measurement Accuracy | Traceability Standard |

| ≤ 20,000 pounds GVWR | ±0.05% of max load-cell force or ±9.8 N (±2.2 lbf) | NIST-traceable |

| > 20,000 pounds GVWR | ±0.05% of max load-cell force or ±39.2 N (±8.8 lbf) | NIST-traceable |

| Evidence Description | Key Findings |

| Dynamometer modification | Creates signals matching horsepower and torque , improving accuracy. |

| Lab test for three-wheelers | Copies driving and measures engine output like speed and power. |

| Multi-axis dynamometer study | Adds a way to measure 3D forces for better accuracy. |

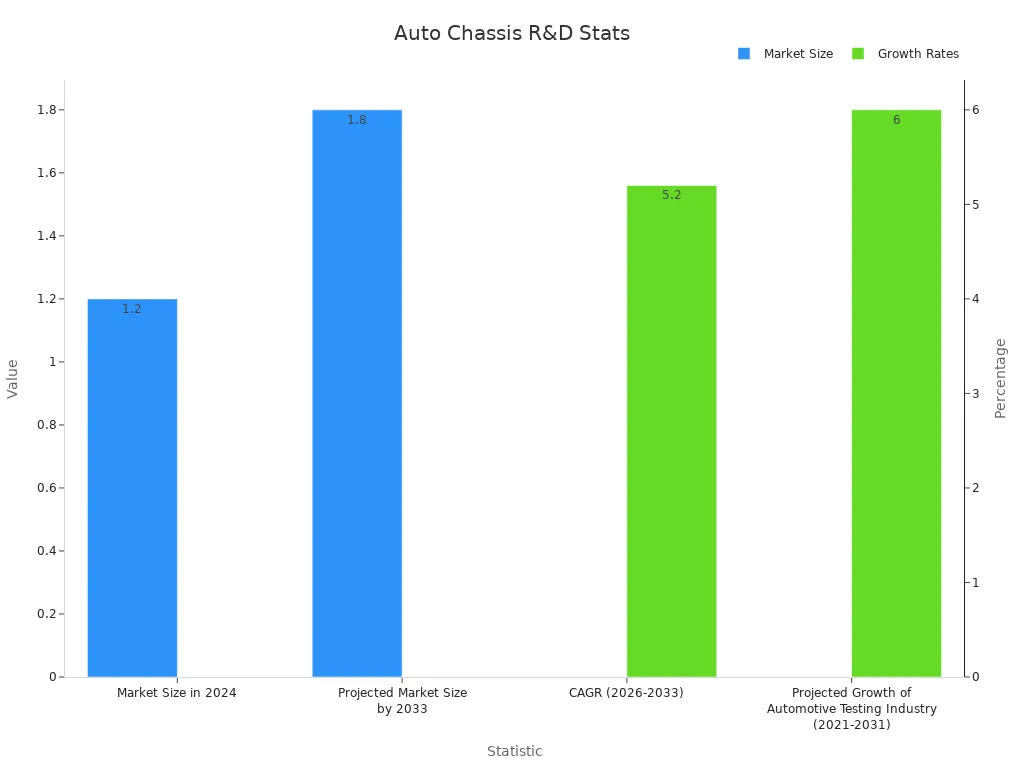

| Fact | Number |

| Market Size in 2024 | $1.2 Billion |

| Market Size by 2033 | $1.8 Billion |

| Yearly Growth Rate (2026-2033) | 5.2% |

| Growth of Car Testing Industry (2021-2031) | 6% |

| Feature | Chassis Dyno | Engine Dyno |

| Power Measurement | Wheel horsepower | Crank horsepower |

| Data Logging | Yes | Yes |

| Software Integration | Yes | Yes |

| Load Simulation | Yes | Limited |

| Calibration | Regular calibration | Regular calibration |